senswork is a Germany-based company specializing in turnkey machine vision, inspection, and optical measurement systems for industrial manufacturing. Pulse 2.0 interviewed senswork CEO and Managing Director Roman Rieger to gain a deeper understanding of the company.

Roman Rieger’s Background

Could you tell me more about your background? Rieger said:

“senswork was founded by Rainer Obergrussberger and me. Rainer is at home working in industrial image processing, automation, and software development, while I come from a background of production and manufacturing engineering. We bring decades of experience from various areas of technology to the table—from mechanical engineering to software architecture. This interdisciplinary approach continues to shape us today: we combine technical expertise with an innovative spirit and an eye for industry and practical application.”

Formation Of The Company

How did the idea for the company come together? Rieger shared:

“The basic idea came about during a course at business school. Rainer and I were at business school together and took seminars on business development. That was the source of the idea of starting a new company. senswork was born out of the need for precise, automated solutions for quality assurance in industrial manufacturing. We see our main task in developing intelligent testing systems that are tailor-made and go far beyond standard solutions. We combine hardware, software, and system integration under one roof.”

Favorite Memory

What has been your favorite memory working for the company so far? Rieger reflected:

“The best moments at senswork are always when we receive direct and honest feedback from our customers. Especially when we hear that our solution not only works but also makes their everyday work easier. When a customer says, ‘We couldn’t have done it without you,’ or when a project team is enthusiastic during acceptance, we know why we do what we do. When existing customers recommend our solutions to other companies in the industry, it confirms our company philosophy. The specialists at senswork are both smart and friendly.”

Core Products

What are the company’s core products and features? Rieger explained:

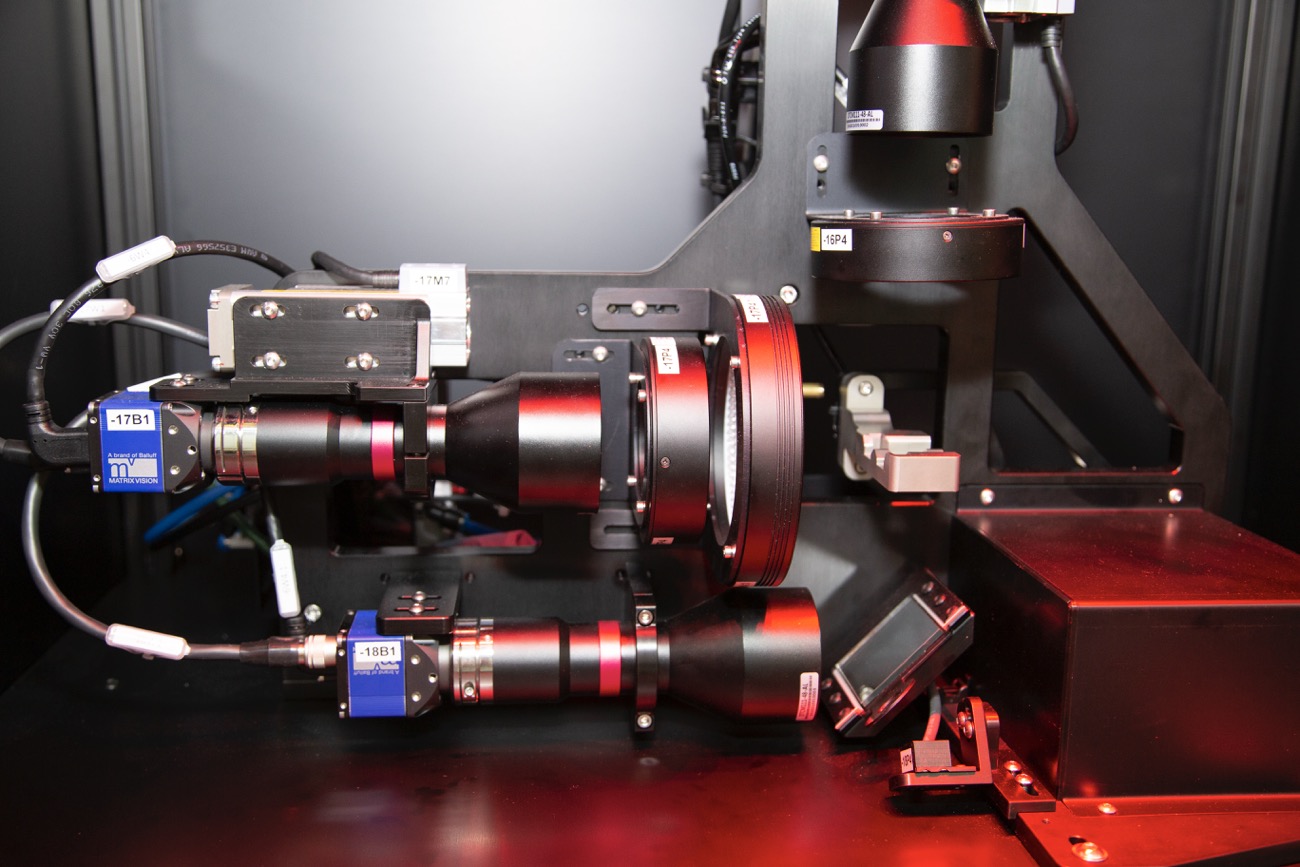

“Our core products are industrial image processing systems for quality assurance, object recognition, and dimensional inspection – at-line and inline. We also develop complete inspection cells, including mechanics, electronics, and software. What makes us special is our end-to-end approach: we think through everything from optics and algorithms to integration into the production line. A key feature is that we develop both hardware and software in-house, which makes us very flexible.

Our most important products include:

VisionCommander: Image processing software for 2D, 3D, and AI-supported inspections

Neuralyze: Software for AI applications in image processing

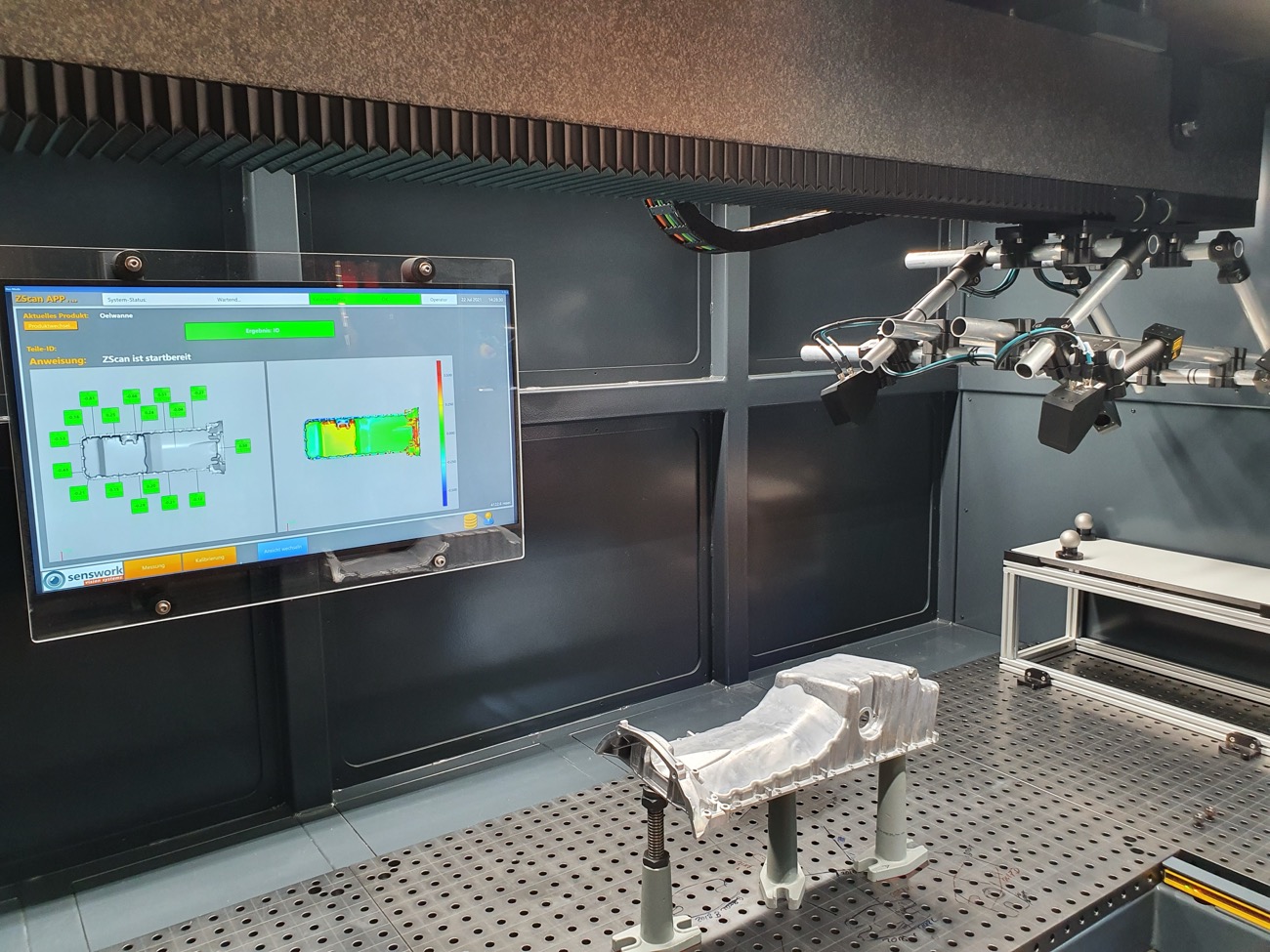

ZScan: System for automatic 3D measurement and IO testing

VisionUnit: Modular testing system for easy integration into machines”

Challenges Faced

Have you faced any challenges in your sector of work recently? Rieger acknowledged:

“One example is a project in battery manufacturing where there were extreme requirements for testing speed and image quality. We solved this by combining customized optics, special lighting, and our own AI-based evaluation—and we did it within a tight timeframe. Our interdisciplinary approach really paid off here.”

Evolution Of The Company’s Technology

How has the company’s technology evolved since launching? Rieger noted:

“In the beginning, the focus was on classic image processing systems with rule-based algorithms. Today, we are increasingly integrating deep learning and 3D image processing. Our products have also undergone significant development in the areas of user guidance and visualization – modern HMIs, web interfaces, and cloud connections are now standard for us. The field of automation integration has also grown considerably in recent years. We can also implement stand-alone machines for optical testing and measurement technology according to customer specifications.”

Significant Milestones

What have been some of the company’s most significant milestones? Rieger cited:

“One milestone was certainly the opening of our Innovation Lab in Munich with a focus on AI and deep learning. We were early adopters of AI; our Vision AI software Neuralyze has been in use by several customers for three years now.”

Customer Success Stories

Can you share any specific customer success stories? Rieger highlighted:

“One particularly exciting project was the introduction of our ZScan 3D measurement system at Magna, a leading global automotive supplier. Magna was faced with the challenge of measuring complex aluminum die-cast parts with high precision and efficiency directly in the production environment—a task that previously could only be accomplished with great effort in a measurement room.”

“With ZScan, we were able to deliver a system that measures flexibly, quickly, and with high precision—without any time-consuming component preparation. The advantages for Magna: up to 76% shorter start-up times for new products and 100% inline inspection, even for pre-series and small series.”

Funding

Are you able to discuss funding and/or revenue metrics? Rieger revealed:

“senswork is a self-financed company with healthy growth. We are growing organically – supported by long-term customer relationships and a steady stream of innovative projects.”

Total Addressable Market

What total addressable market (TAM) size is the company pursuing? Rieger assessed:

“Industrial image processing is a growing billion-dollar market. We see strong demand in areas such as e-mobility, semiconductors, and automation, particularly in Europe and Asia. It is difficult to give an exact figure. I can confirm that we are growing very well, even if we are only active in niche applications.”

Differentiation From The Competition

What differentiates the company from its competition? Rieger affirmed:

“We don’t think in terms of pigeonholes. Instead, we take a holistic view of every project – from mechanics and optics to software. We offer tailor-made complete solutions in industrial image processing, combining hardware with our own software development and a focus on deep learning (AI). This makes us technologically independent and very fast. In addition, our in-depth knowledge of the process technology of various production and manufacturing processes brings considerable added value to our customers.”

Future Company Goals

What are some of the company’s future goals? Rieger emphasized:

“We want to further develop our technologies in the field of vision AI and strengthen our presence at international trade fairs such as Automate 2025 in Detroit.”

Additional Thoughts

Any other topics you would like to discuss? Rieger concluded:

“Perhaps the most important thing to mention at the end: senswork is more than just technology. We are a team that works with passion, curiosity, and a genuine joy in solving problems. When you work with us, you don’t just get a system—you get a reliable team that thinks ahead. It’s also worth noting that we are able to roll out machine vision solutions and provide the necessary service for our customers worldwide.”